Mill Manager

Features & Specifications

Pallet-Track suite of software designed for the pallet industry.

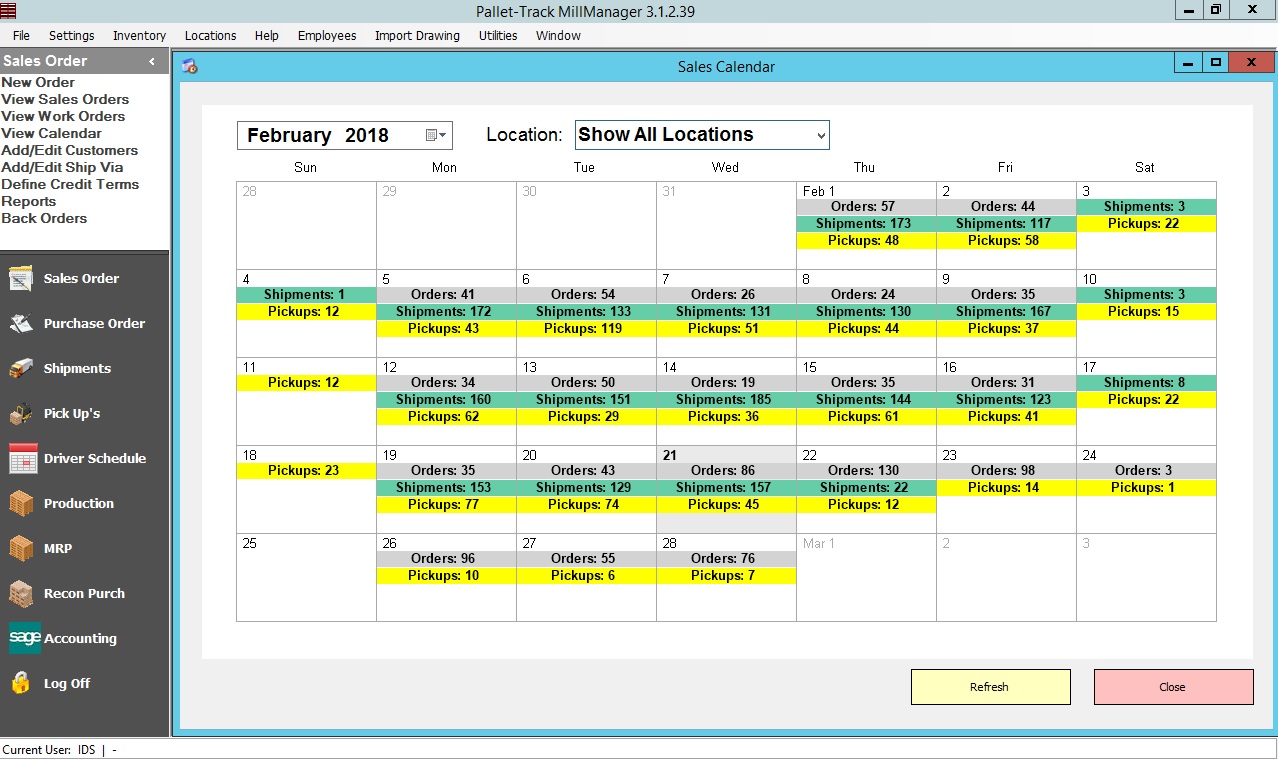

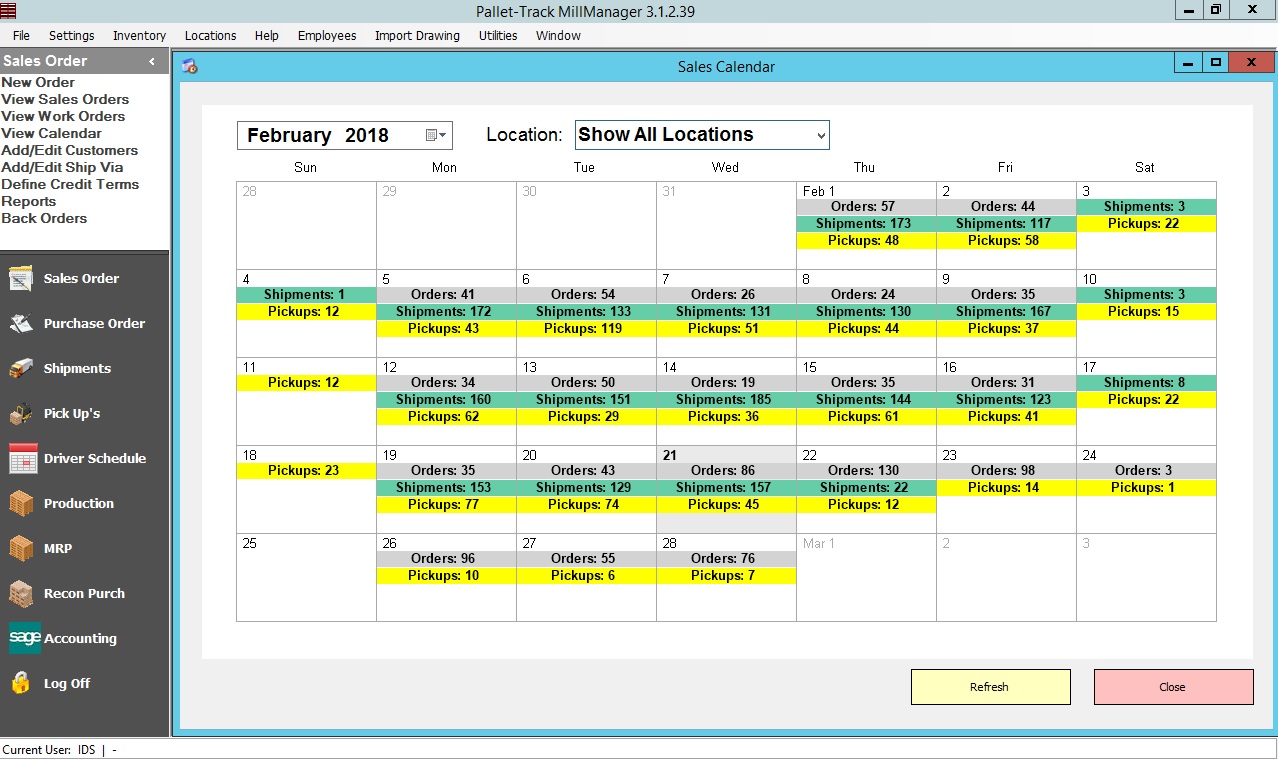

Sales Order Module

- Create orders for customers with specific pricing per customer, per shipping location

- Track pricing and purchase history for each customer

- Assign trailer types, specific production notes, drawings and more to any product per customer

- View all orders, pick-ups and shippers in our calendar feature - reprint any document with a click of a button

- Online ordering is automatically entered into the system as if it was entered by your employees.

Purchase Order Module

- Issue unique purchase orders to vendors

- Track when and what products were received on each order

- Attach true cost to inventory when receiving

- Close purchase orders when complete or pricing changes to avoid receiving inventory at wrong price

- Information automatically available to Pallet Track® Receiving system

Receiving Module

- Key-in PO number to view products ordered

- Select product and optionally print bar coded tags to identify product received

- Automatically adjusts inventory and re-calculates weighted average costs

- Generates a static receiving report to cross reference with invoices

Customer Order and Work Order Module

- Choose customer and customer specific products to create customer order

- System checks inventory for stock of products ordered and reserves the quantity

- Work orders are generated for all orders and identifies out of stock products and quantity needed

- Inventory structure is used to identify components needed to produce product and is included on work order

- Customer order history is stored for analyzing purchasing habits, frequency, etc.

Inventory Adjustment Module

- Inventory is automatically adjusted in real-time at each stage of each process

- Set re-order minimums/maximums for every item

- Maintain an average weighted cost for ever item

- Track quantities used for any date range / View history of any item

Production Module

- Schedule production based on orders and Bill of Material required for each product

- Schedule components to saw lines, pallets to production lines and secondary processes like Heat Treating

- Calculates cost of items produced based on materials consumed plus overhead

- Collect production times, employee compensation and store for analyzing

Shipping Module

- Scan/enter work/customer order to generate shipper (scanner optional)

- Ability to adjust quantities of products shipped

- Maintain open balances or close work orders

- Stores data for referencing against returned signed shippers.

- Dynamic Driver's Schedule / automatically populate E-Signature accounts

- Missed Shipment Analysis

- Loading Schedule

Accounting Module

- Scan signed shipper to automatically export information into accounting system

- Tracks all open shippers and invoiced shippers

- Stores all data to compare against lost and potentially un-invoiced orders.